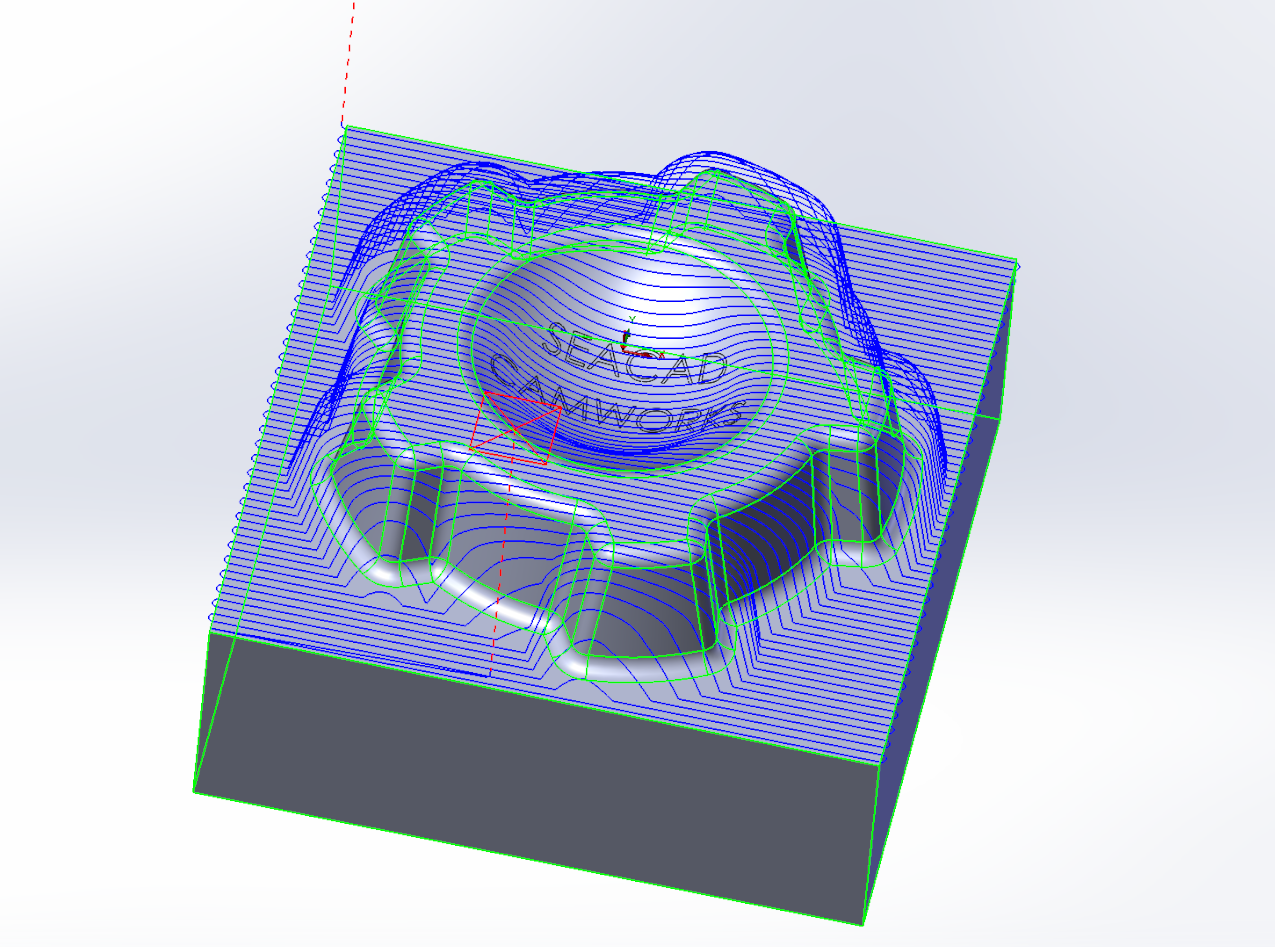

3-Axis Milling Operations for Multi Surface Feature in SOLIDWORKS CAM and CAMWorks

3 axis milling operation is advanced milling operation such as surfacing, where the tool is free to move in X, Y and Z axis simultaneously. Ideal for surfacing and detailing.

3 Axis Milling modules for CAMWorks are built on the core fundamentals of :

- Feature-based machining - Reduces programming time by as much as 90% compared to other traditional 3 axis CAM software

- Knowledge-based machining - Allows you to capture and reuse the best practices for various operations

- Full toolpath associativity to solid models - Automatically updates the tools paths and CAM data

- CAMWorks VoluMill™ - the ultra-high performance toolpath generator for rough milling operations

While CAMWorks 3 Axis cycles are developed for speed, accuracy and efficient memory usage, it also ensure that simple and complex parts can be cut quickly and accurately with a high-quality toolpath.

In this blog, we are going to learn about the 3 axis operations for multi surface feature in SOLIDWORKS CAM and CAMWorks:

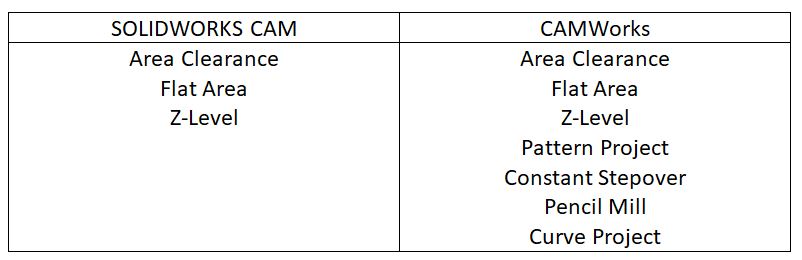

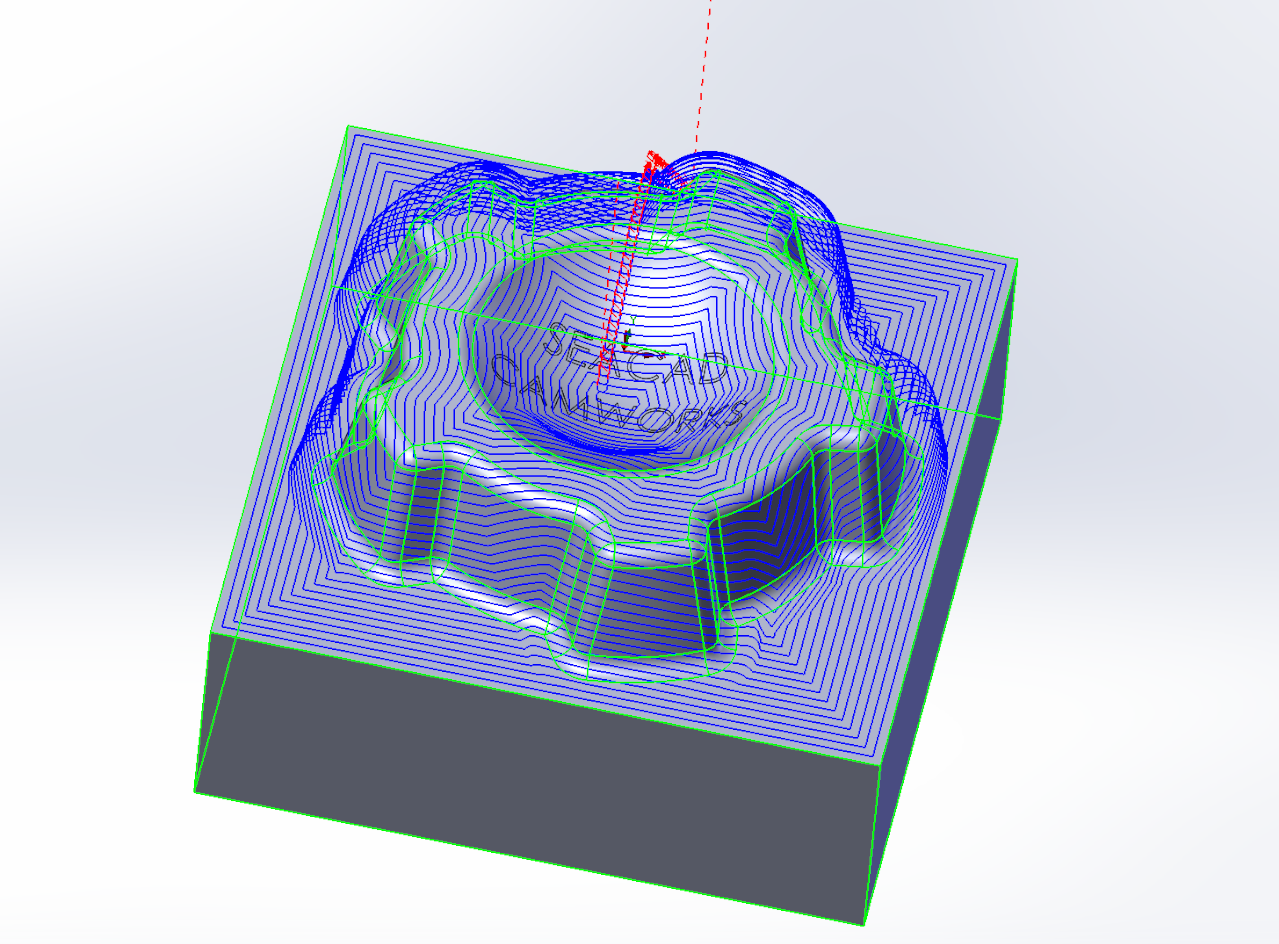

Area Clearance

Area Clearance is the 3 axis roughing operation.

Use the Area Clearance operation to remove the material between the stock or contain area and the selected feature at decreasing Z depth levels by:

- Making a series of parallel cuts across the stock (Lace Pattern)

- Making a series of parallel cuts by pocketing out towards the stock (Pocket Out pattern)

- Making a series of parallel cuts by pocketing in towards the core (Pocket In - Core pattern)

- Using Adaptive Pattern is only available in CAMWorks

- Using VoluMill pattern is only available in CAMWorks

Flat Area

The Flat Area cycle uses a pocket out pattern to remove material from feature faces that are flat and parallel to the XY machining plane. Toolpaths are only generated on completely flat areas. If a face/surface has even a small gradient, toolpath will not be generated. This cycle can be used for finishing where excess material has already been cleared and supports single or multiple depths of cut.

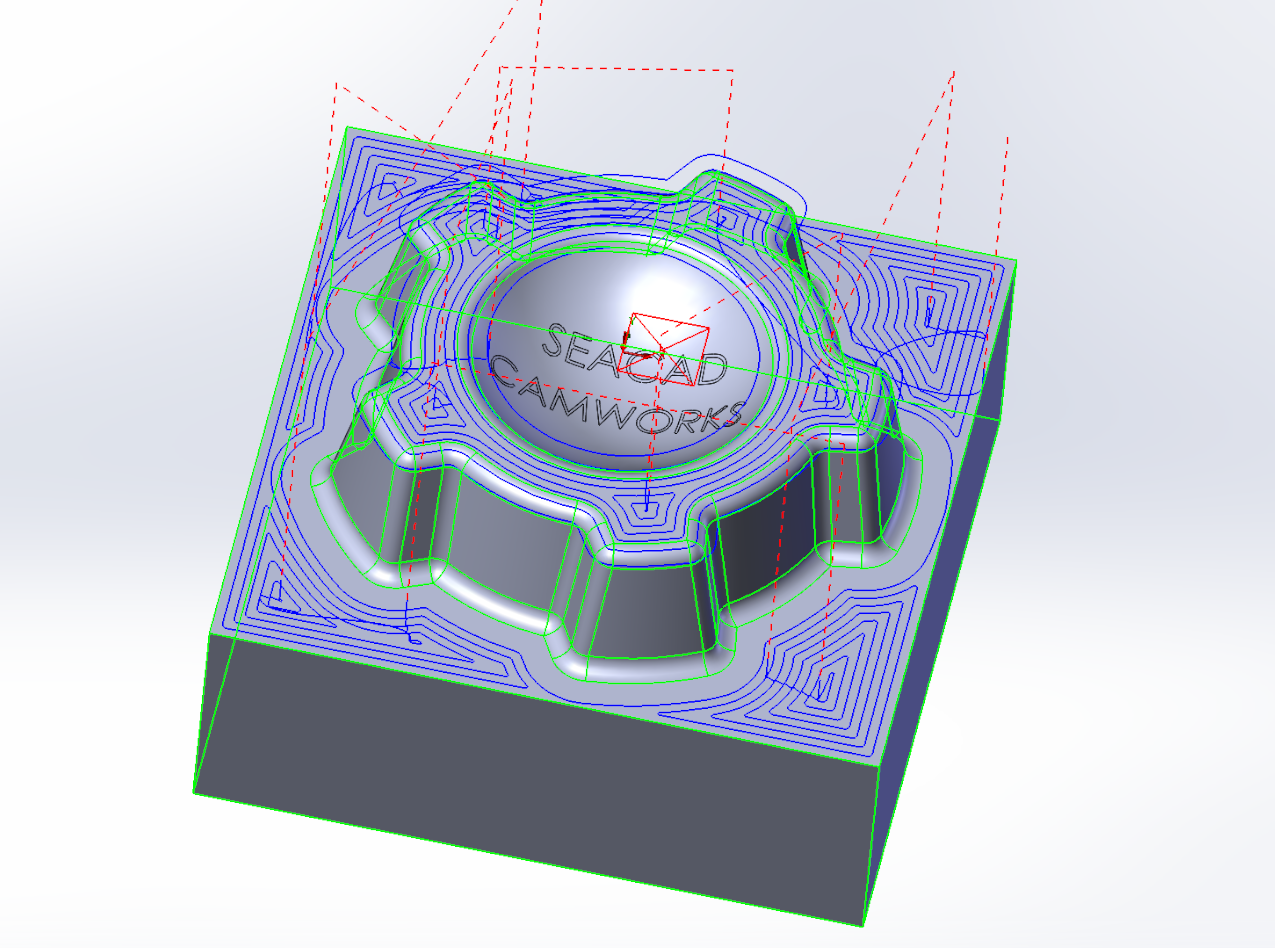

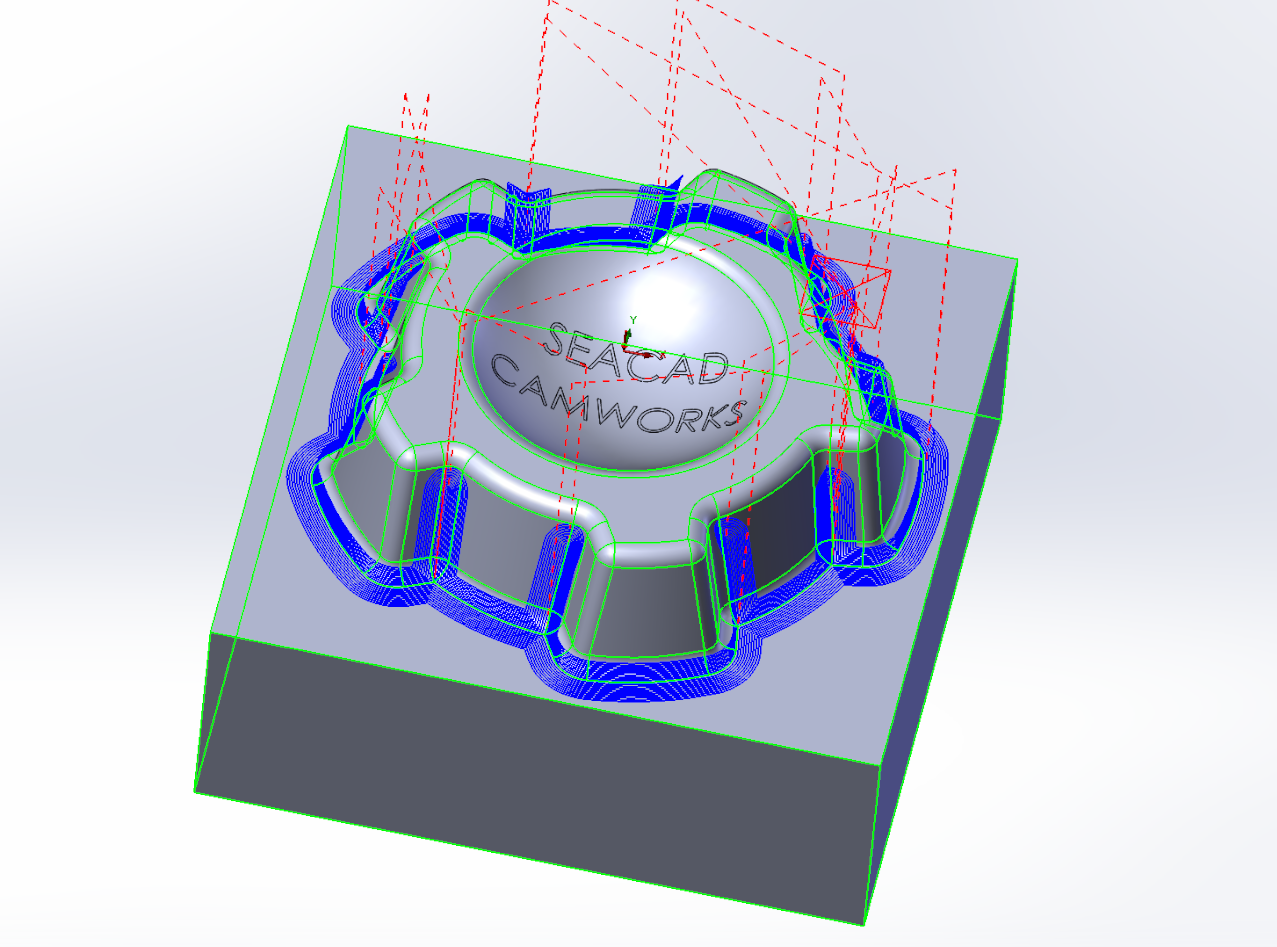

Z-Level

The Z-Level cycle is a finish contouring cycle that removes material by making a series of horizontal, planar cuts. The cuts follow the contour of the feature at decreasing Z levels based on the Surface Finish specified. Cutting starts from the highest location of the model and works downward.

Pattern Project

The Pattern Project operation is a multi-surface finishing cycle that removes material based on the selected pattern: Slice, Flowline, Radial and Spiral. These patterns have unique characteristics that make them appropriate for semi-finishing and finishing selected areas or the entire model.

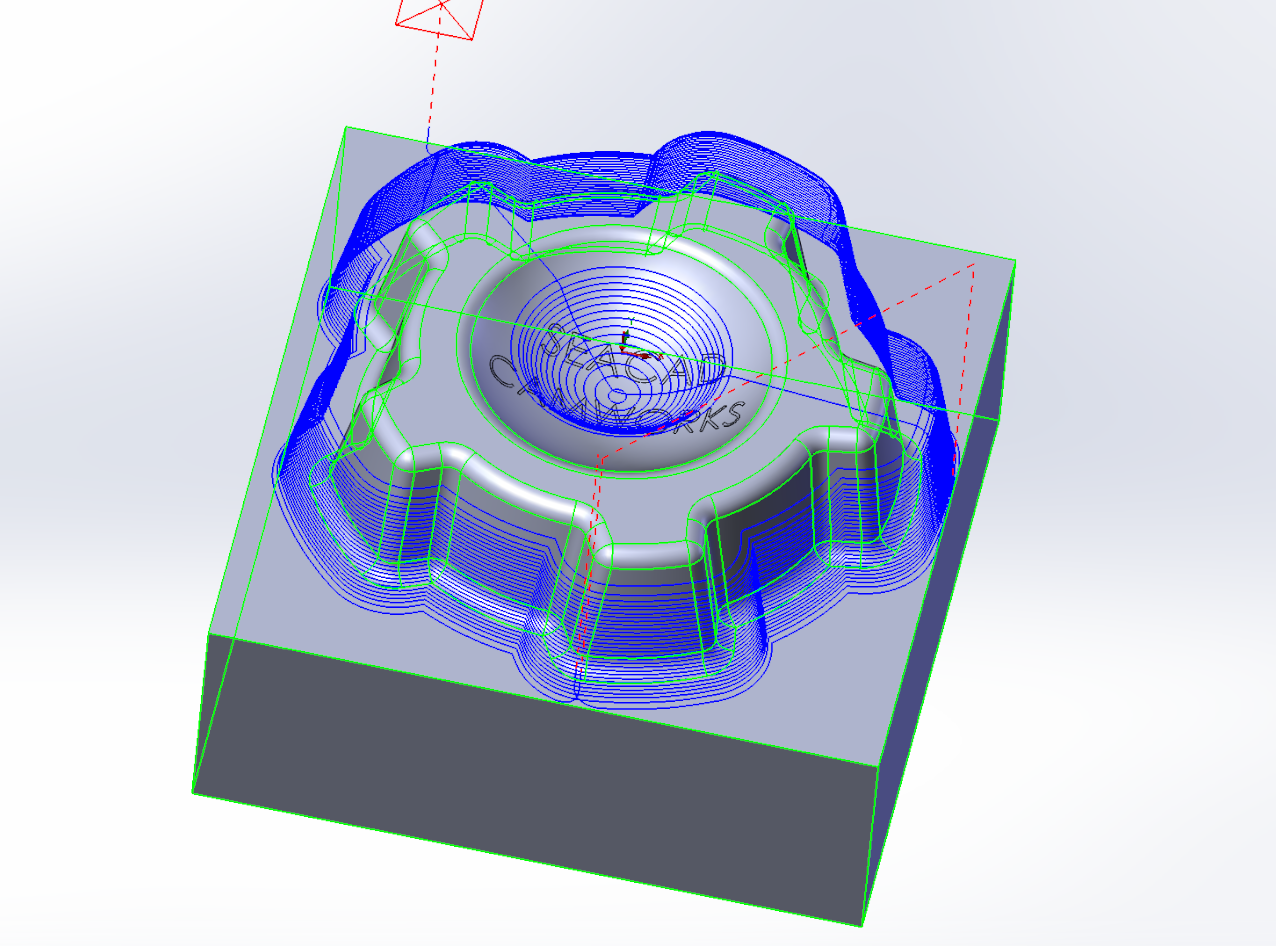

Constant Stepover

The Constant Stepover operation removes material by maintaining a constant user-defined stepover relative to the surface. The 3D stepover method generates a toolpath with a true constant stepover regardless of the slope of the feature faces. This method produces the most consistent surface finish on features whose faces have both shallow and steep slope angles.

Pencil Mill

The Pencil Mill cycle generates toolpaths to finish machine corner areas using a single pass or multiple constant passes.

Corner areas are defined where the radius of curvature of the feature is less than the radius of the tool.

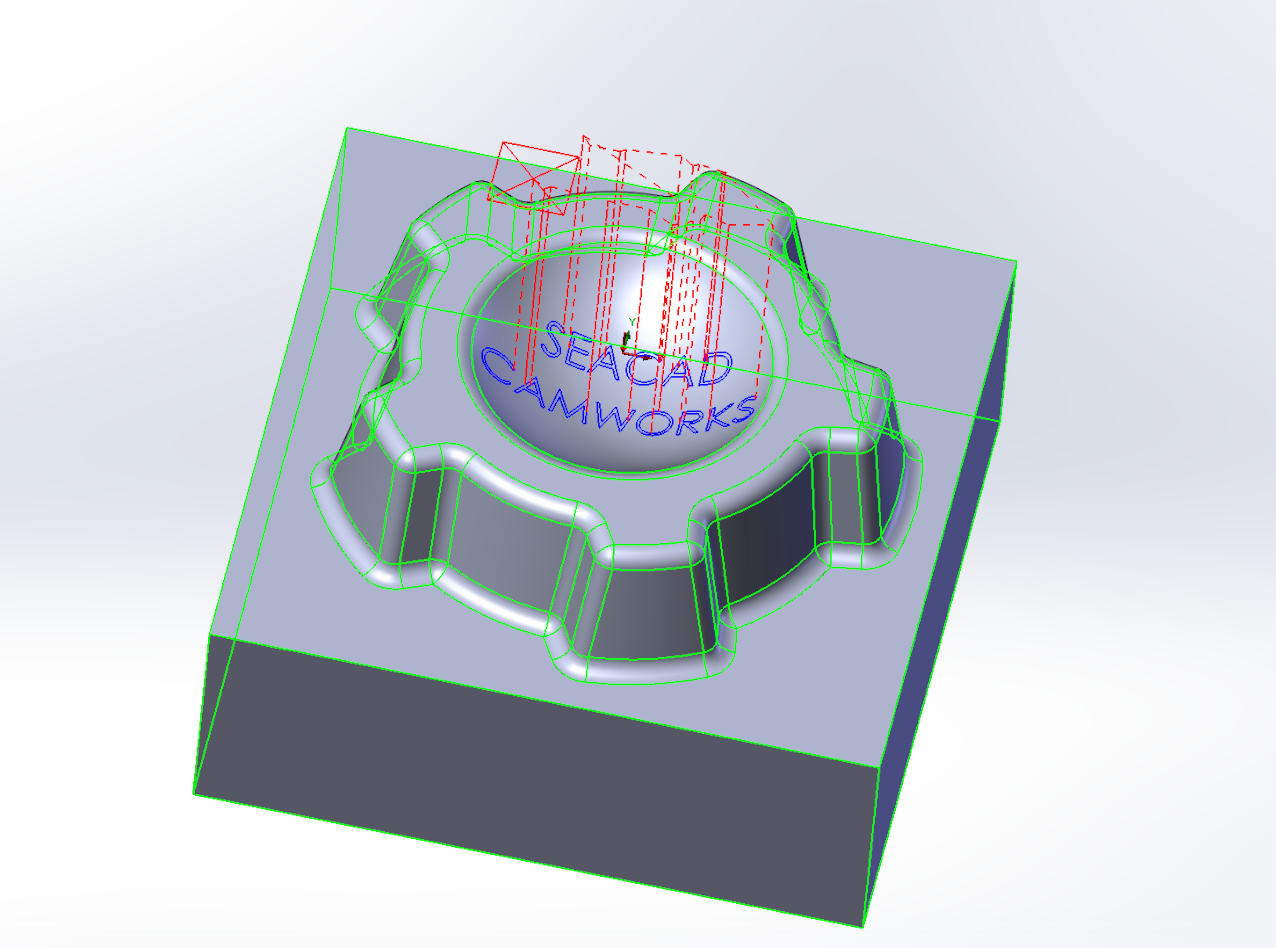

Curve Project

The Curve Project cycle removes material by projecting selected 2.5-axis Engrave or Curve features onto the faces/surfaces of a Multi-Surface feature and generating toolpaths along the projected entities. This cycle ensures consistent depth of cut along the surface, and can be accomplished in single or multiple passes.

Do you want to know more about the SOLIDWORKS CAM and CAMWorks? Please contact us marketing@seacadtech.com, thanks.