Simulation professionals across many industries are familiar with terms Finite Element Analysis, commonly known as FEA Simulation and Computational Fluid Dynamics, CFD Simulation. Both approaches can solve your thermal analysis problems but which simulation software is best for your product design needs?

Thanks to SOLIDWORKS Simulation solutions, you can now get the most out of your design validation needs. SOLIDWORKS Simulation solutions provide a robust and an easy-to-use portfolio of analysis tools for predicting a product’s real-world physical behavior by virtually testing CAD models.

SOLIDWORKS Simulation tools and solutions allow you to virtually test ideas and subject your designs to real-world conditions. You can evaluate performance, raise product quality – and reduce the costs of prototyping and physical testing in complex material models.

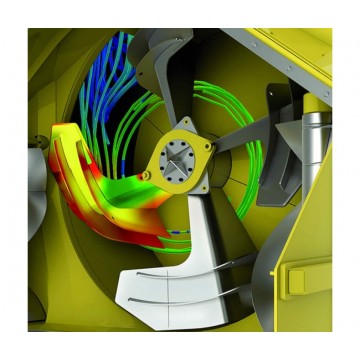

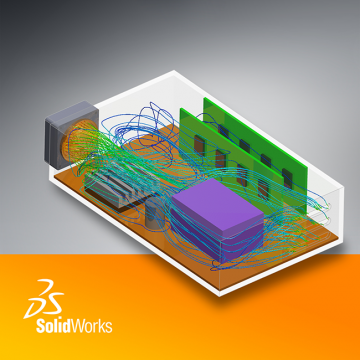

SOLIDWORKS Simulation portfolio of structural analysis tools and solutions allows you to utilize Finite Element Analysis (FEA) software and Computational Fluid Dynamics (CFD) simulation to predict real-world behaviors of products and analyze complex material behavior by virtually testing CAD models.

Why Choose SOLIDWORKS Simulation?

Simulation solutions for SOLIDWORKS feature a range of structural analysis tools and act as a virtual testing environment for simulation data, with analysis capabilities such as:

- Linear Static Analysis

- Nonlinear Analysis

- Dynamic Analysis

- Finite Element Analysis (FEA)

- Frequency Analysis

- Fatigue Analysis

- Thermal Analysis

- Buckling Analysis

- Structural Optimization

- Drop Test Analysis

Choose from the following SOLIDWORKS Simulation packages we offer:

- SOLIDWORKS Simulation Standard

- SOLIDWORKS Simulation Professional

- SOLIDWORKS Simulation Premium

- SOLIDWORKS Flow Simulation