CAMWorks - Integrated CAD & CAM Software to Reduce Time & Costs

Fully integrated CAM Software for SOLIDWORKS®

Program Smarter

Reduce programming time by up to 90% with fully integrated CAD/CAM, feature-based programming and automatic feature recognition.

Machine Faster

Decrease cycle time by as much as 85% and increase tool life up to 500%, even in the hardest materials, with revolutionary high speed machining options.

Achieve consistent, high-quality output by capturing your shop's best programming and machining practices with knowledge-based machining and CAMWorks TechDB™

Why CAMWORKS ?

- Faster Programming Time

- Fully integrated with industry leading CAD platforms - SOLIDWORKS®

- CAD and CAM data are stored together in one file

- File translation issues are eliminated

- Manufacturing data is automatically updated when design changes are made

- Feature-based programming uses intelligence built into the software to identify operations, tools, and feed/speed rates

- Automatic Feature Recognition automatically identifies all the programmable features in a part

2. Consistent, High-Quality Manufacturing

- Knowledge-Based Machining significantly reduces programming time

- Tolerance-Based Machining helps achieve superior tolerance and surface finish requirements by reading MBD and PMI data and selecting the machining strategies to meet the specified tolerances

- CAMWorks patented Technology Database (TechDB™) captures and reuses your shop's best programming and machining practices for consistent results

- Provides a company-owned database to store employee knowledge and preferences

3. Complete Post Processor Support

- Post processors for over 2000 machine tool and controller combinations

- Includes a Universal Post Generator (UPG) that enables users to modify existing posts or develop new posts

CAMWorks Products

CAMWorks Standard

CAMWorks Standard is the ultimate CAD/CAM programming base product.

- Wide range of 2.5 axis and 3+2 milling, including rotary milling

- Turning capabilities, including sub-spindle support

- High-speed machining using 2.5 axis VoluMill

- Probing capabilities

CAMWorks Milling Standard expands the functionality of CAMWorks Standard with additional milling functionality.

- 3 axis rough milling with rest machining

- 3 axis finishing cycles including Z-level (waterline), flat area, pattern project, constant step-over

- Additional 3 axis operations including pencil milling, 3 axis rest machining, and curve project for engraving on 3D surfaces

CAMWorks Turning Standard expands the functionality of CAMWorks Standard with additional functionality for lathes and multi-tasking machines.

- Mill-turn with C, Y & B axis capabilities

- Dual turret with pinch turning

- 2 & 4 axis turning with up to 11 axis mill-turn capabilities

CAMWorks Milling Professional includes all the functionality in CAMWorks Milling Standard and additional advanced milling capabilities.

- Multi-axis operations including undercutting, fillet machining and NURB surface machining

- Mill-turn with C, Y & B axis capabilities

CAMWorks Turning Professional includes all the functionality in CAMWorks Turning Standard and provides advanced turning and mill-turn capabilities.

- CAMWorks Sync Manager for synchronous machining on mill-turn machines

- CAMWorks Virtual Machine Standard for full machine simulation with collision detection

CAMWorks Premium is the ultimate integrated CAD/CAM programming solution. It includes all the functionality in CAMWorks Milling Professional and CAMWorks Turning Professional, plus more.

- Complex 4 axis milling

- Full simultaneous 5 axis milling

CAMWorks Add-on Products

CAMWorks VoluMill

CAMWorks VoluMill is an ultra high-performance toolpath engine within CAMWorks for 2.5 axis and 3 axis milling roughing operations.

- Significantly reduces cycle times and increases cutting tool life

- CAMWorks 2.5 axis VoluMill is included with all CAMWorks products, and 3 axis VoluMill is available as an add-on

PrimeTurning™

CAMWorks supports Sandvik Coromant's PrimeTurning™ which offers the flexibility for turning operations in all directions.

- Reduces cycle time for turning by 50% or more

- Increases insert tool-life by 500% or more

- Full toolpath support for turning in all directions

CAMWorks Virtual Machine

CAMWorks Virtual Machine virtually proves out CNC programs with true G-code machine simulation to avoid collisions and broken tools.

- Reduce setup time by 50% or more

- True G-code machine simulation, eliminates dry-runs

- Avoid collisions and extend machine life

CAMWorks Wire EDM

CAMWorks Wire EDM includes cutting-edge functionality that takes the design model to G-code in one click.

- Searches and identifies the part for machine-able features automatically

- Generates all the operations with the user's preferences and settings

- Creates the toolpaths and posts the G-code

NESTINGWorks is a fully associative SOLIDWORKS® add-in that optimizes material usage for sheet metal fabrication, woodworking and more.

- Maximize material usage

- Optimize your designs

- Save on production cost

CAMWorks ShopFloor

Promotes digital manufacturing by providing 3D models with MBD & PMI data and CNC programming information to the shop floor in a single, compact digital format.

- Meet Smart Manufacturing and Industry 4.0 initiatives

- Improve communication on the shop floor with digital technology

- Increase production, decrease turnaround time and reduce waste

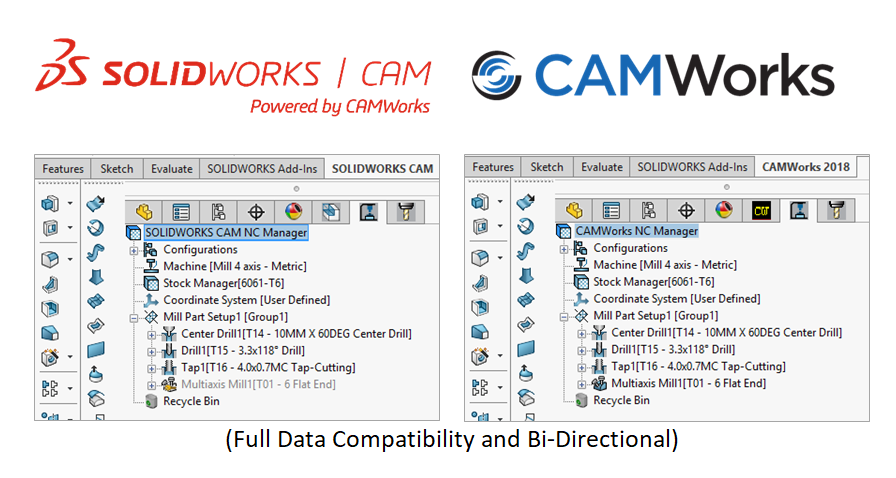

SOLIDWORKS CAM and CAMWorks Functionality Matrix

* 2.5 Axis Milling Plus includes 2.5 Axis Milling plus Area Clear Roughing, Flat Area and Z- Level Finishing

* 3 Axis Milling L1 adds a Z-Level Finishing combined cycle for steep/shallow machining

* 3 Axis Milling L2 adds Pattern Project, Constant Step, Pencil Milling, 3 Axis Rest Machining, Curve Project, and Legacy Rough & Finish Mill

* 3 Axis Milling L3 adds Multi-Axis Operations including Undercutting, Fillet Machining, and NURB Surface Machining

Want to know more? Request a CAMWorks DemoCAMWorks